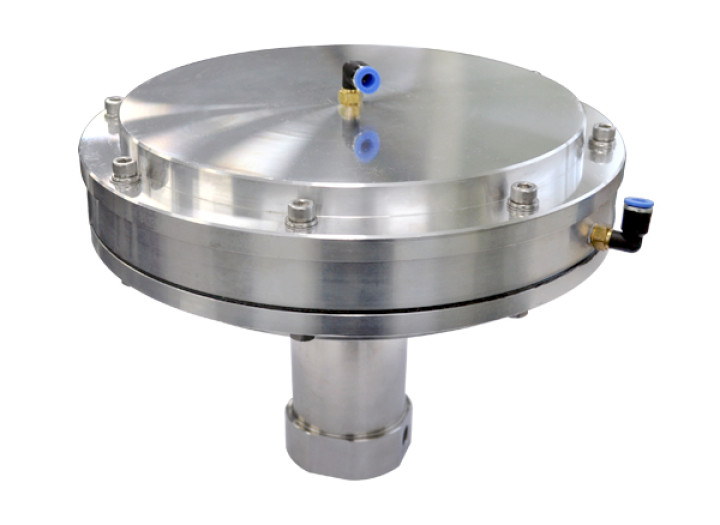

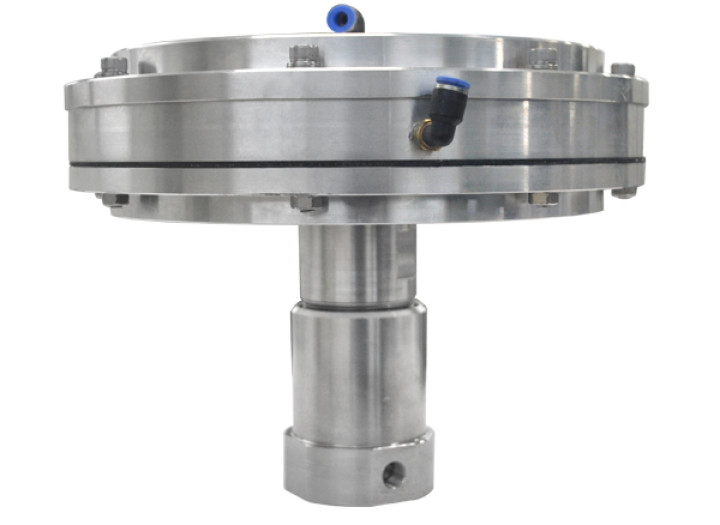

ABPR ABPR (Air Operating Back Pressure Regulator) - 20000

| Product Name | Air Operating Back Pressure Regulator 20000 |

|---|---|

| Features | Oprerating Air Pressure - 20000psi, 3bar |

| Features | Setting pressure can be adjusted through electronic regulator (10,000psi 0~5bar, 20,000psi 0~3bar),and can be controlled remotely |

| Features | Six different relief pressure ranges |

| Features | Bubble-tight shut-off at all reseat pressures |

| Features | High flow Cv=0.6 model optional |

| Features | Ambient Operating & Fluid Media Temperature -55℃ ~ 100℃ |

List

본문

Detail view

ABPR (Air Operating Back Pressure Regulator)Setting pressure can be adjusted through electronic regulator,and can be controlled remotely

|

| BPR, Back pressure regulator (or Back pressure reducer regulator) it is based on a contrary concept to the regulator that is generally used. Unlike the pressure regulator which is widely used to control the pressure of the outlet, the BPR steadily maintains the inlet pressure which you need. The hiflux BPR can be used for pressure of up to 15000psi (inlet pressure) and prevents water leaks by applying the type of ceiling which is suitable for the features of the gas or liquid that is being used. Setting pressure can be adjusted through electronic regulator (10,000psi 0~5bar, 20,000psi 0~3bar), and can be controlled remotely. |

|

OperationWe will guide you through how it works.

|

I will talk about our product by giving an example. By installing the BPR, a fluid (or gas) flows from inlet to outlet. Next, I will talk about a case where the inlet pressure is maintained at 90bar (1300psi / 91kg in other unit). ① First of all, turn the BPR handle, completely open it and then operate the pressure device. ② As the BPR is completely open, the pressure is released through the outlet and the pressure isn’t filled. ③ At this time, you can see that pressure within the vessel has increased if you slowly turn the BPR handle and check the gauge. ④ If you turn the handle until the pressure is 90bar and stop, the pressure within the vessel is maintained at 90bar. Even if the pressure device continuously works, pressure surpassing 90bar is discharged through the outlet and the pressure within the vessel is maintained continuously at 90bar. |

|

FeaturesWe will guide you through the product’s features and benefits.

|

Oprerating Air Pressure : 20000psi, 3bar Oprerating Air Pressure : 20000psi, 3bar Setting pressure can be adjusted through electronic regulator (10,000psi 0~5bar, 20,000psi 0~3bar),and can be controlled remotely Setting pressure can be adjusted through electronic regulator (10,000psi 0~5bar, 20,000psi 0~3bar),and can be controlled remotely Six different relief pressure ranges Six different relief pressure ranges Bubble-tight shut-off at all reseat pressures Bubble-tight shut-off at all reseat pressures High flow Cv=0.6 model optional High flow Cv=0.6 model optional  Ambient Operating & Fluid Media Temperature -55℃ ~ 100℃ Ambient Operating & Fluid Media Temperature -55℃ ~ 100℃

|

|

InformationWe will inform you about product specifications.

|

|

SpecificationWe will guide you through the model name, specifications, and dimensions for each product.

|

As all sizes are for reference, they can be changed without any notification. As all sizes are for reference, they can be changed without any notification. Please contact us for details or send to online inquiry, we will give you respond as soon as possible. Please contact us for details or send to online inquiry, we will give you respond as soon as possible. For the most effective fitting, it is recommended to use Fitting Accessory and Tubing of HIFLUX. For the most effective fitting, it is recommended to use Fitting Accessory and Tubing of HIFLUX.

|

|

ApplicationCheck out the products applied in various fields.

|

High pressure fluid handling components for the chemical, petrol chemical, water-jet, research and oil and gas industries. High pressure fluid handling components for the chemical, petrol chemical, water-jet, research and oil and gas industries. As our products are divied into pressures of 5500~150000psi, body type and port size you can use them according to the specifications which you want to use. As our products are divied into pressures of 5500~150000psi, body type and port size you can use them according to the specifications which you want to use. Our products generally are produced with stainless steel materials, but they can be manufactured with other materials on demand so that various fluids and gases can be used Our products generally are produced with stainless steel materials, but they can be manufactured with other materials on demand so that various fluids and gases can be usedPlease inquire with us about special materials apart from the above-mentioned materials, such as STS316, HC-276, Inconel, Titanium, Nickel. |

|

|

NumberingWe will guide you through product classification and ordering options.

|

|||||||||||||

|