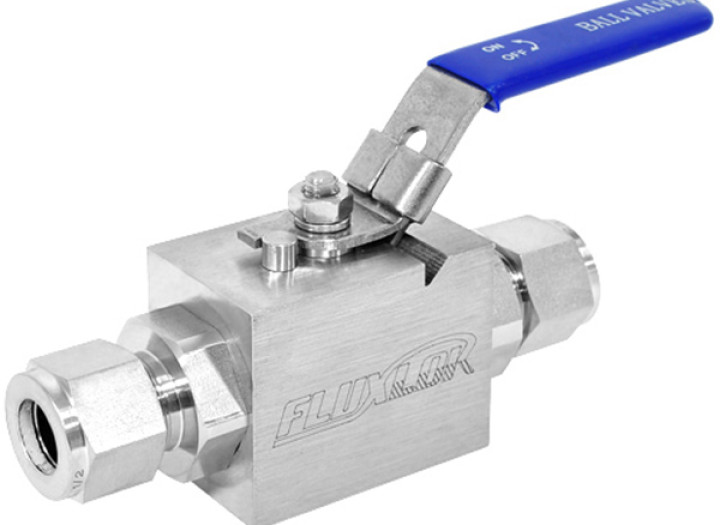

Lok Type Valve Lok Type Ball Valve - HBV10

| Product Name | Lok Type Ball Valve (HBV10) |

|---|---|

| Max Pressure | 3,000psi (206bar) |

| Features | Live-Loaded packing system double ferrule design |

| Features | Stainless Steel 316 Material Body |

| Features | 1/8" ~ 1" Lok fitting & NPT outlet port. |

| Features | allows bidirectional flow. |

| Features | Low operating torque, compact, maximum-flow design |

List

본문

Detail view

Lok Type ValveIt can be applied to various process and system configuration of the whole industry such as plant industry, chemical, water jet, oil, gas, etc

|

| HIFLUX Lok Fitting (FLUXLOK) can be applied for various industries such as chemical, petrol chemical, waterjet , fliud research industries, gas and oil industries. |

|

FeaturesWe will guide you through the product’s features and benefits.

|

Allows bidirectional flow. one-piece instrumentation ball valves. Allows bidirectional flow. one-piece instrumentation ball valves. Max Pressure : 5,000psi (344bar). Max Pressure : 5,000psi (344bar). Temperatures up to -53~148℃ (-65~300°F)). Temperatures up to -53~148℃ (-65~300°F)). Stainless Steel 316 Material Body. Stainless Steel 316 Material Body. 1/8" ~ 1" Lok fitting & NPT outlet port. 1/8" ~ 1" Lok fitting & NPT outlet port. ON & OFF Type. ON & OFF Type. Panel mounting. Panel mounting. Low operating torque, compact, maximum-flow design. Low operating torque, compact, maximum-flow design. does not require system pressure to seal. does not require system pressure to seal. has virtually no dead space. has virtually no dead space. Technical Information : [ Tubing O.D Hardness] Technical Information : [ Tubing O.D Hardness]

|

|

StructureWe will guide you through the structure of each product.

|

|

|

SpecificationWe will guide you through the model name, specifications, and dimensions for each product.

|

As all sizes are for reference, they can be changed without any notification. As all sizes are for reference, they can be changed without any notification. Please contact us for details or send to online inquiry, we will give you respond as soon as possible. Please contact us for details or send to online inquiry, we will give you respond as soon as possible. For the most effective fitting, it is recommended to use Fitting Accessory and Tubing of HIFLUX. For the most effective fitting, it is recommended to use Fitting Accessory and Tubing of HIFLUX.

|

|

InformationWe provide information on pressure ratings and flow rate data for each temperature.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure-Temperature Ratings Designed to take into account temperature changes in outdoor environments and high temperature processes. Designed to take into account temperature changes in outdoor environments and high temperature processes. Instrumentation ball valves exposed to dynamic temperature conditions before installation may lose their initial packing load. Packing adjustment may be needed. Instrumentation ball valves exposed to dynamic temperature conditions before installation may lose their initial packing load. Packing adjustment may be needed.

Testing / Flow Data at 100°F (37°C)

Every integral-bonnet needle valve is factory tested with nitrogen at 1000 psig (69 bar). Every integral-bonnet needle valve is factory tested with nitrogen at 1000 psig (69 bar). Seats have a maximum allowable leak rate of 0.1 std cm3/min. Seats have a maximum allowable leak rate of 0.1 std cm3/min.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

AssemblyWe will guide you through the assembly process of fitting and tube.

|

1. Fully insert the tube into the fitting and against the shoulder; rotate the nut finger-tight. 2. Mark the nut at the 6 o’clock position. 3. While holding the fitting body steady, tighten the nut one and one-quarter turns to the 9 o’clock position. |

|

ApplicationCheck out the products applied in various fields.

|

FLUXLOK is brand for Lok fitting of HIFLUX Co., Ltd. FLUXLOK is brand for Lok fitting of HIFLUX Co., Ltd. Suitable for chemical, oil refining, research, oil and gas companies, this product is used for various pressures. Suitable for chemical, oil refining, research, oil and gas companies, this product is used for various pressures. Has not torque transition for tubing in installation. Has not torque transition for tubing in installation. Can be checked and inspected easily during the first installation. Can be checked and inspected easily during the first installation. |

|